Case Study: Endoscopic Camera

460H 3-CCD Camera Head

for Smith & Nephew

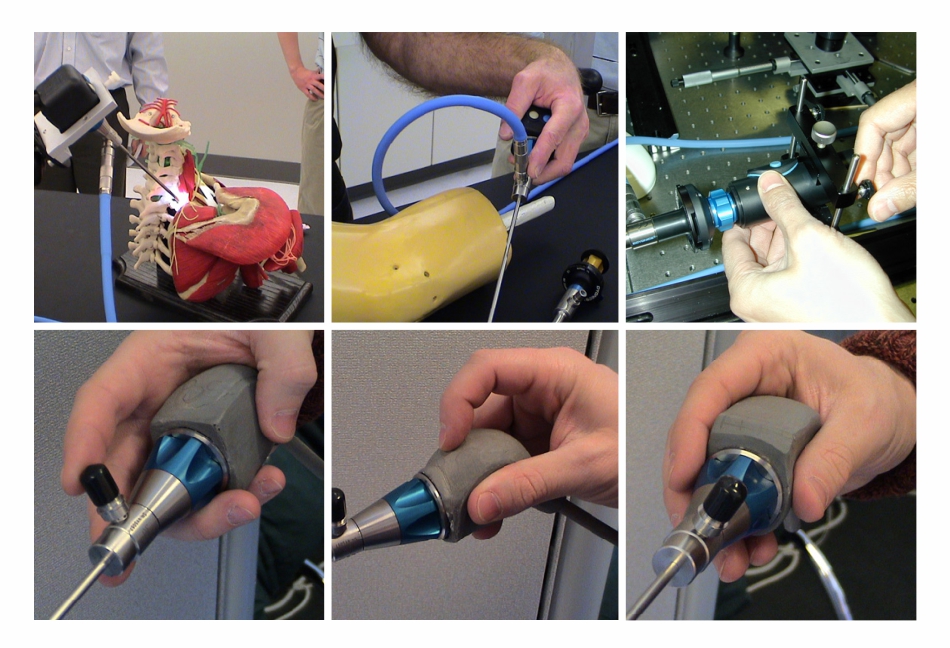

The 460H Camera is a new three-chip endoscopic camera system providing superior image quality, digital output, the option of steam sterilization, and compatibility with the previous generations camera components. The project goal was to develop a small, light-weight, ergonomic camera design that minimizes surgeon hand fatigue while enabling intuitive one-hand operation. To quote from Smith & Nephew:

“Excellent engineering, efficient design, and exceptional performance –

the qualities you expect from the leader in endoscopic imaging.”

User-friendly features include an ergonomic, “surgeon-tested” form that fits comfortably in the palm of the surgeon’s hand. The convenient three-button controls provide tactile identification and intuitive operation of all camera functions.

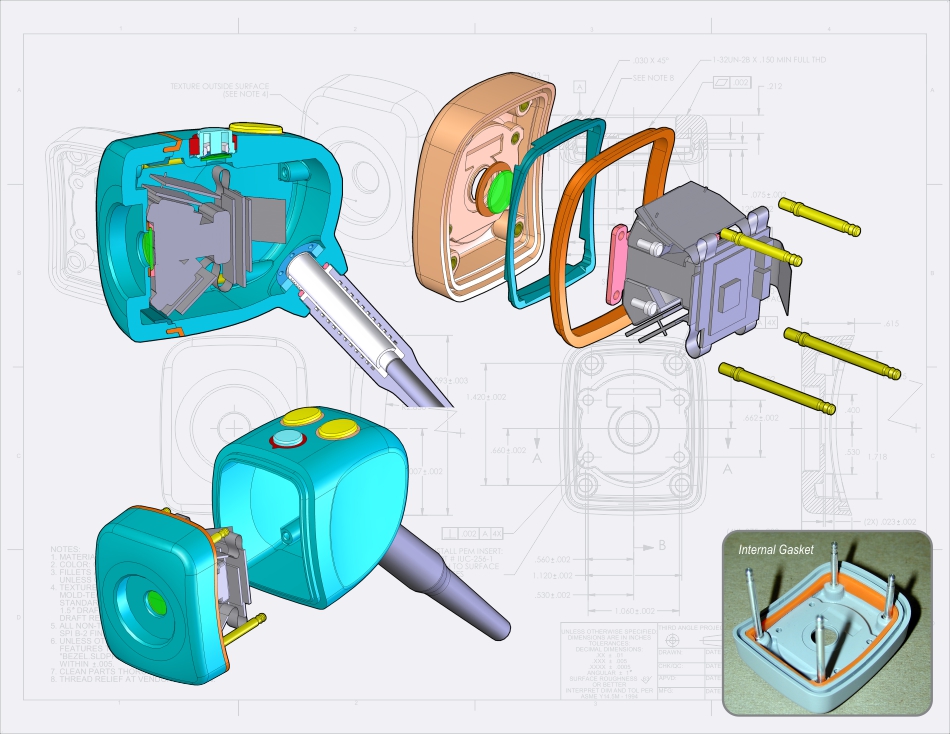

Because of tight delivery schedules and exacting tolerances, the body of the camera is machined as opposed to injection molded. This presented specific design challenges to provide adequate access to the CNC cutters. Polyphenylsulfone (PPS) was used for its hydrolytic stability, thermal stability, toughness, and resistance to environmental stress cracking.

In order to withstand repeated steam sterilization, the camera requires three gaskets to protect the sensitive components. The front bezel is assembled using custom-designed pins that are press fit into bosses in the rear case.

Services:

- Form Refinement

- Component/Assembly Design

- SolidWorks Database Development

- Project/Client Management

Deliverables:

- Detailed 3D SolidWorks Database

- Complete Production Documentation

- 3D File Exports for Production

(Note: This project was completed by Warren Ginn while an employee of Integrated Design Systems. Visit www.idsys.com for more information.)